ZW3D 2021 v25.05 Crack Free Download [Latest]

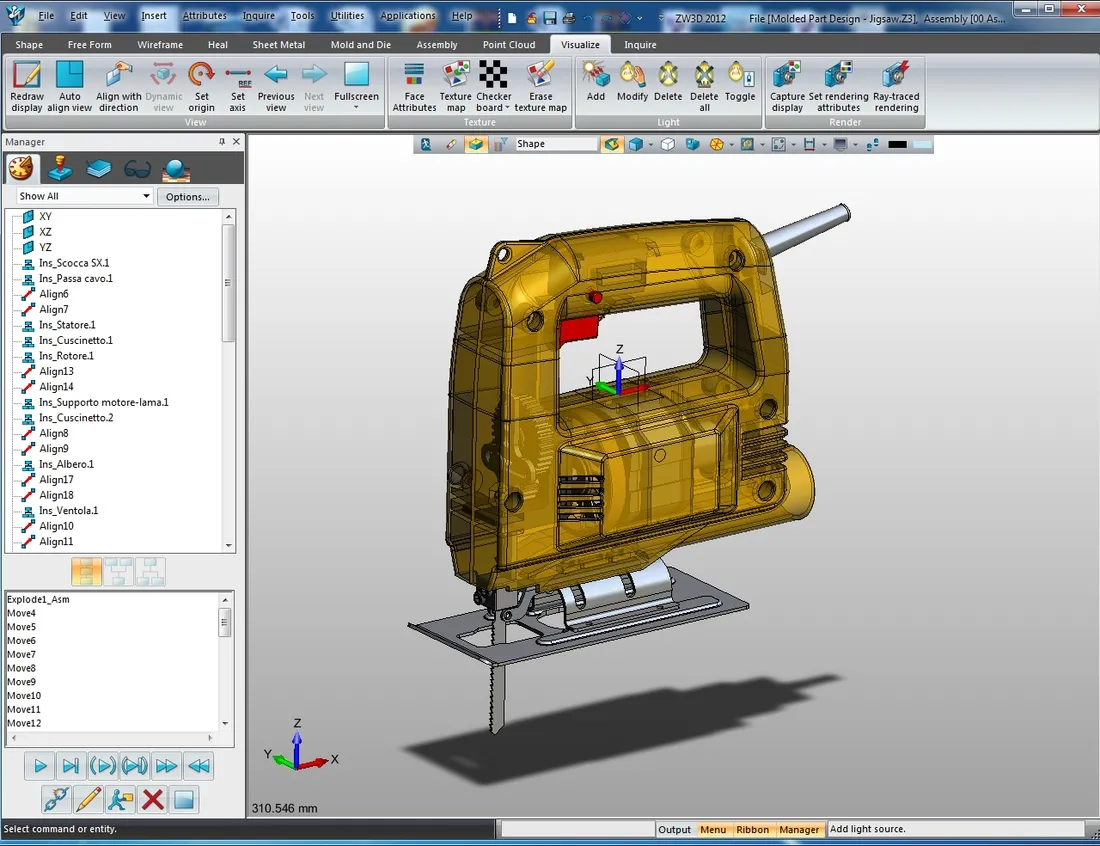

ZW3D Crack is a universal CAD/CAM system that allows product development at all stages of design, from the creation of a sketch of the project and ending with the manufacture of products on CNC machines. Supporting the most advanced technologies, the ZW3D geometry modeling engine offers a data streaming solution coupled with unique memory management techniques, which allows you to work with large files containing complex geometry in real time.

Versatility of modeling

With ZW3D you can create three-dimensional models of parts and assemblies of models, 2D drawings, perform reverse engineering, simulate motion, as well as create your own component bases that greatly simplify the modeling of complex objects. ZW3D supports the principle of hybrid modeling, that is, it makes it possible to work with a model as a solid, surface or wireframe object in the same three-dimensional space. In addition, the program allows you to import various parts and assemblies into one working file, placing them at different levels.

Compatibility with common Formats

• ZW3D formats ZW3D™ has a wide range of features, high performance and data processing speed, and is also compatible with other CAD/CAM applications.

• ZW3D™ recognizes Solidworks®, Catia®, Autodesk Inventor®, Pro/Engeneer®, UniGraphics®, ACIS data formats well, reads and saves data in DWG/DXF, Parasolid, STEP, IGES formats:

• ZW3D 2017 supports Catia file format V5/6R2016, NX11, Creo 3.0, SolidWorks 2017, SolidEdge ST9 and Inventor 2017.

• Allows you to export a 3D model to IGES, STEP, STL, Catia and other file formats.

The ZW3D™ Parts Library

includes a built-in library of over a million ANSI, ISO and DIN international standards from the world’s leading manufacturers, making it easy to create fully functional models and assemblies.

Direct Editing

SmoothFlowTM technology combines the speed and flexibility of direct modeling with precise control of parametric design dimensions, maintaining a complete model building history, making ZW3D™ one of the most advanced CAD applications in the world.

Fast Mold and Die Creation

The ability to process disjointed geometry and the use of built-in databases allows you to select electrodes and create your own die sets as quickly and efficiently as possible. ZW3D allows one-step data calculation to create cores and cavities, which, in combination with the new electrode multi-selection tools, greatly simplifies the mold design process.

Preparation for processing on CNC machines

Integrated CAM technology allows for 2-5 coordinate processing of an object. Intelligent 3D Feature Machining automatically selects processing methods, including high-speed processing and residual material removal. Adaptive Feedrate Control maximizes tool life and minimizes machining time.

3-Axis Machining

Built-in 3D Feature Machining technology automatically analyzes the topology of the model and applies the most suitable toolpaths. Thanks to this, any holes and embossed surfaces are processed automatically in ZW3D, reducing, as a rule, preparation time by 50%, and processing time by 30%.

Sketching made easy

The design of most products starts with 2D sketches that represent the geometry of the model. The whole set of tools is available for modeling sketches: a lot of geometric shapes that will help the designer save time, using several sketches or geometric shapes to assemble, Sketch doctor, which helps to ensure the relationship of sketches, make analysis and get rid of limiting factors.

Assembly and design

Ease of use and rich features allow users to easily create complex and complex designs, use top-down and bottom-up design when working with large models, perform compatibility checks, have a quick selection of tools, and find errors in the processing of results at an early stage of work. Using animation techniques, designers can demonstrate basic operations as they would in real life.

Reverse Engineering

With built-in reverse engineering, designers can use pointers, STL, scan or report data to build 3D images, just like when preparing models for CNC machines, to fill in gaps, build surfaces, and form knots. The software can be connected to a 3D printer to create a more realistic model.

Sheet metal design

Possibility to prescribe various characteristics of sheet metal: edge, flange sections, holes, latches, and so on. It is also possible to collapse or expand the projection, taking into account the geometry of solid bodies or space, using the Solid&Surface Hybrid modeling technology in ZW3D;

Thickness Variation Analysis

When designing a product, it is very important to rely on design analysis and thickness variation analysis data to ensure that the product structure meets the criteria and functionality. You can get information about the thickness, deviation in the corners of any model in any projection. Deviation up and down is marked with different colors. Thickness difference analysis shows the minimum and maximum element size.

Converting 3D Models A

2D image can be converted to a 3D model, just like a 3D image can be converted to a 2D projection. The program automatically creates 2D associative models with projection, separation and detailing, you can sign dimensions and annotations, including ANSI, ISO, DIN, JIS, GB standards are supported, materials, holes, electrodes are automatically combined with tables, tables and stencils of symbols are easily configured , two-dimensional images, hatching patterns.

Checking the interaction of moving parts

During development, design quality checks and useful tools help the designer to notice an error or gaps in time and fill them. You can visually examine the relationship between components by highlighting the features of their separation. An interaction check is also performed in order to see the parts in a complete assembly, the user is given information: volume, number, area of interacting sections. Drag tool (transfer of objects from place to place) helps the designer to make sure that all components take their place.

Animated Simulation

Use vivid animation to demonstrate various operations: sliding, assembling and disassembling. This video is a vivid example of such a presentation: checking and modeling movement with certain restrictions, creating an animation of the assembly and disassembly of the part. After saving the video in * .avi format, you can start the presentation.

External and internal reversal of parts

For most parts, roughing, finishing, grooving, threading, turning, drilling are available. Features of the material, surface, shape are recognized very easily. The reversal program is feature rich yet easy to use.

Easy to learn and use

Self-learning ZW3D™ is greatly facilitated by the built-in Show-n-Tell™ learning system.

Each task of this system consists of a sequence of actions shown and described in detail on the screen. Performing these tasks helps to understand the basic principles and rules of working with the program.

System requirements:

• OS: Windows 10, Windows 8/ 8.1, Windows 7 – x64

• Processor: Intel Core 2 Duo @2GHz or above, or equivalent AMD® processo

• RAM: Recommended configuration: 4G or above

• Video:

– OpenGL 3.1 or above

– nVIDIA Quadro FX 580 @ 512MB or above, or equivalent AMD Graphic card

– Minimum configuration: 1024 x 768 VGA with True Color

– Recommended configuration: 1280 x 1024 VGA with True Color or above

Our Mission

“To provide free and easy access to software for people who can’t afford the high costs of licensed programs. We believe that everyone should have the opportunity to use quality software, regardless of their financial situation.”

Disclaimer

We hope you enjoyed our article on Star Crack and the free software they provide. If you have any questions or comments, please feel free to leave them below. We would love to hear from you!

Download Links/Mirrors

Download ZW3D 2021 v25.05 – x64 (1.38 GB):

In order to gain access, you need to authorize on the site